Strength Guarantee

Safety Production

Perfect safety production, fire control and other management system

Perfect fire safety equipment and facilities

Clear fire safety signs

Environmental protection measures are rigorous, safe and effective

All kinds of safety equipment and facilities are complete

Electrostatic Standard Unit of Guangdong Province

Information Management

Information management platform

Traceability

Quickly grasp the problem product flow

Effectively control the source of problem products to prevent proliferation

Achieve fast traceability

Increase customer confidence

Quality Assurance

Product quality and safety in the first place

Advanced quality testing equipment

Quality safety assurance system

Full-time technical department and quality management department

Effective control of raw materials and finished product testing

Ensure that the product quality qualified rate of 99.99% and above

Process Control

Production automation, scale

Pipeline closed feeding

Achieve environmental protection, clean, safe production process control

High productivity, low cost, low loss, high quality

Guarantee customer order supply

Logistics Distribution

Outsourced hazardous chemical logistics company

Car LTL vehicle delivery, domestic dedicated line

Effective vehicle collocation

Dedicated staff planning and follow-up

Responsible, efficient, civilized and safe delivery

Urgent Plan Guarantee Demand

Customer Service

Full-time customer service personnel responsible for customer basic information records

Order delivery tracking service within 2 hours of order confirmation

Customer satisfaction tracking service, Customer complaint tracking service

Customer Receivables Tracking Service

Customer first, service first

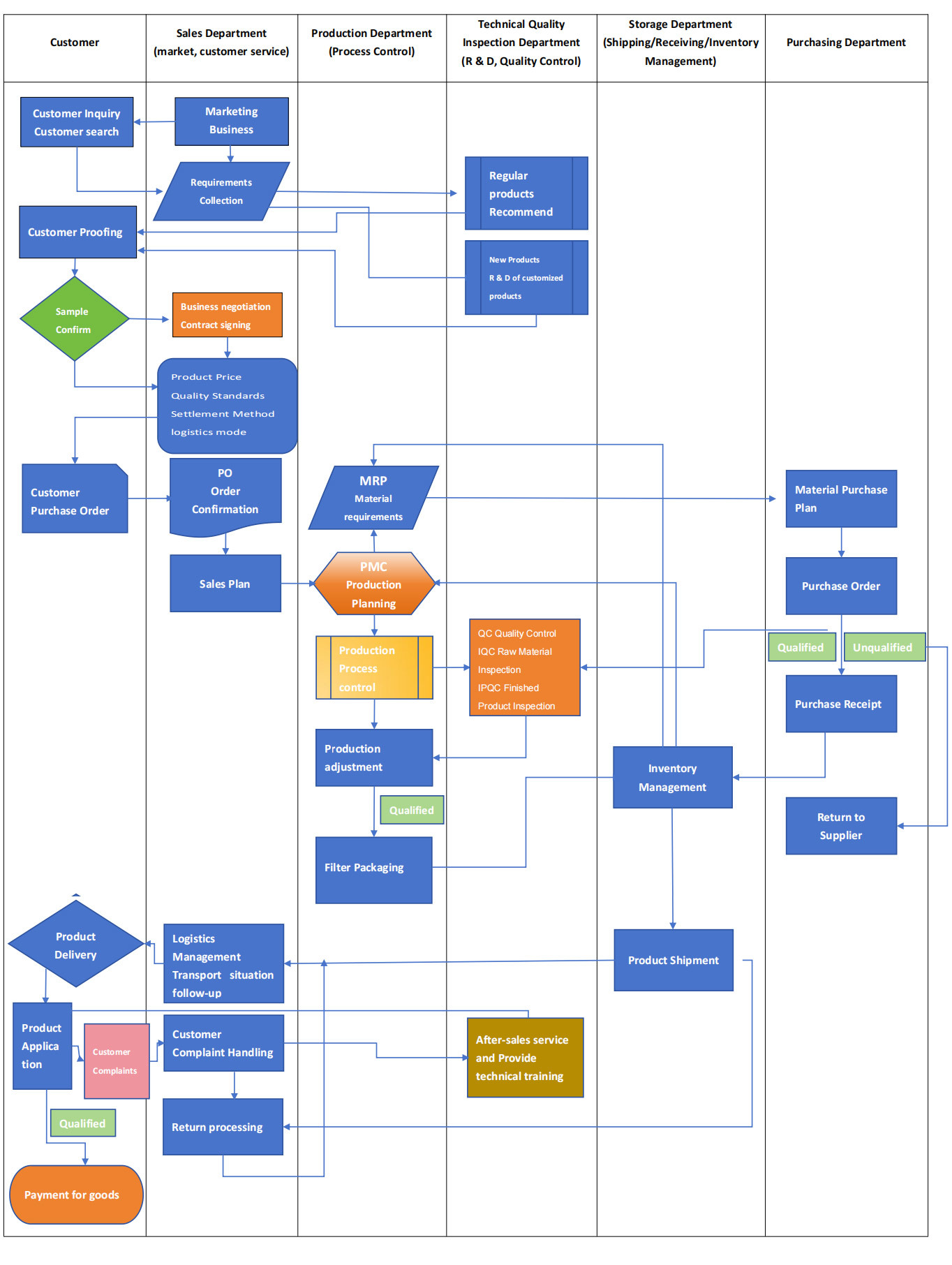

Service Process

FAQ

Common problems with liquid inks-electrostatic whiskers and electrostatic markings

Common Problems of Liquid Ink-Blocking Plate

Liquid Ink FAQ-Whitening

Liquid ink FAQ-knife line